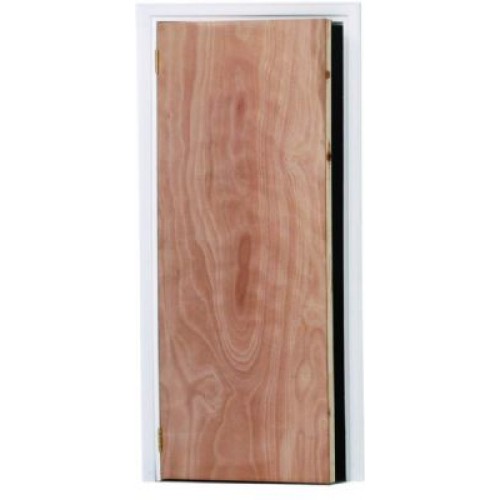

FLUSH DOORS

Many modern doors, including most interior doors, are flush doors; Flush Doors can be turned into Painted and Polished style, CNC Grooved, PVC Foiled, Laminated Doors, Veneer Doors, MDF Doors and designer Doors option with various combinations. We follow BIS (Bureau of Indian Standards)standards in all kinds of door making Other details are as follows:-

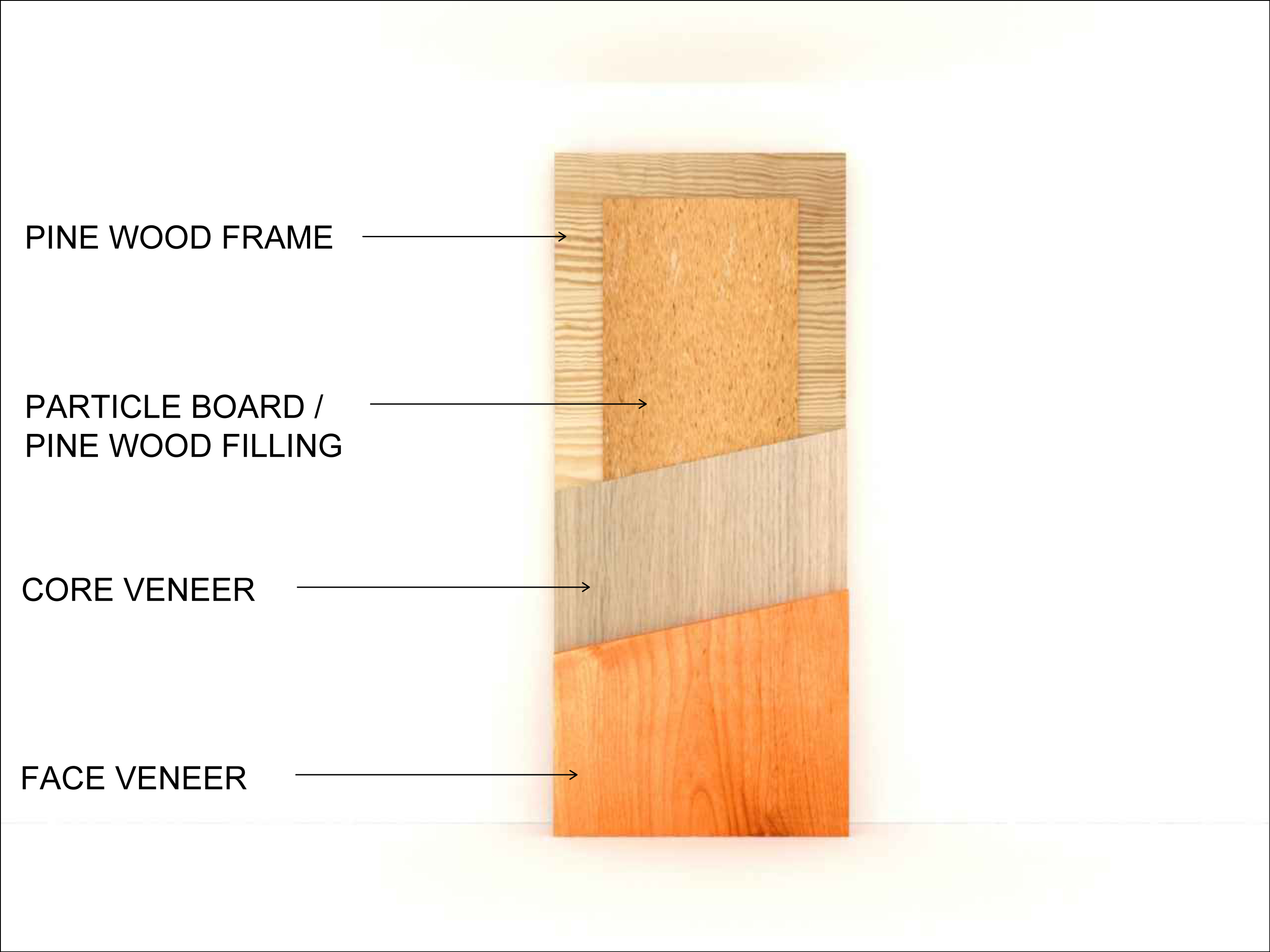

- Stiles and rails:- As above, but usually smaller. They form the outside edges of the door.

- Core material:- Material within the door used simply to fill space, provide rigidity and reduce druminess.

- Calibrated Solid Particle Board:- This door infill material is made from extract of Solid Pine wood and Industry Grade Adhesives, the process is fully mechanized and proven in industry. The final product is solid (with no gaps or hollow structure) and doesn't warp (dabak) as per changing temperature zones in India. Can be used across any temperature zones across India.

- Hollow-core:- Often consists of a lattice or honeycomb made of corrugated cardboard, or thin wooden slats. Can also be built with staggered wooden blocks. Hollow-core flush doors are commonly used as interior doors.

- Lock block:- A solid block of wood mounted within a hollow-core flush door near the bolt to provide a solid and stable location for mounting the door's hardware.

- Stave-core:- Consists of wooden slats stacked upon one another in a manner similar to a plank & batten door (though the slats are usually thinner) or the wooden-block hollow-core (except that the space is entirely filled).

- Solid-core:- Can consist of low-density particle board or foam used to completely fill the space within the door. Solid-core flush doors (especially foam-core ones) are commonly used as exterior doors because they provide more insulation and strength.

- Skin:- The front and back faces of the door are then covered with wood veneer, thin plywood, sheet metal, fiberglass, or vinyl. The wooden materials are usually layered with the grain alternating direction between layers to prevent warping. Fiberglass and metal-faced doors are sometimes given a layer of cellulose so that they may be stained to look like real wood.

Thickness available:- 30mm, 35mm and above (tolerations as per BIS Standards)

Infill:-

Calibrated Solid Particle board made from Pine Wood

Solid Pine Wood